Services

GROUND IMPROVEMENT – SOIL SOLUTIONS

Since, 2016, Powerbetter has organically grown into a combined ground improvement -soil solutions company, where specialist dynamic /impact / rolling compaction deep ground improvement applications are adopted within our application designs and digital monitoring validation capabilities along with the core services of Powerbetter’s well established and experienced Soil Stabilisation / Soil Improvement Modification (SIM) techniques.

Geotechnical Reviews / Project Profiles / Application Designs

· Method Specifications / Combination Strategies / QA Validation

· Verification Programs / Technical Reports / Full Warranties

POWERBETTER STRATEGY

Our new strategy has extended our soil stabilisation / modification / solidification 35-year leadership in the UK and Irish markets by introducing our own specialist dynamic / impact / rolling compaction ground improvement applications (RIC-9T / PCR-26T) through organic growth, particularly in developing markets, and targeting more complex ground improvement projects requiring a combination of SIM-Lime/Cement &/or RIC-9T / PCR-26T packaged ground improvement / soil solutions.

Expansion / Growth / New Technologies / Digital Monitoring

Early Involvement / Partnering / Value Engineering

Combination of Applications / Continuous Improvement / Competitive Edge

MIX-IN-PLACE… SOIL IMPROVEMENT / MODIFICATION (SIM)

Soil Stabilisation

Soil Modification

Soil Solidification

Moisture Conditioning

In civil engineering, soil stabilisation / modification / solidification are techniques to refine and improve the engineering properties of soils. These properties include mechanical strength, permeability, compressibility, durability, plasticity and moisture control.

Powerbetter holds a mobile plant licence for the treatment of soils and contaminated material, substances or products from the Environment Agency, permit number UP3092ZE, in accordance with the standard rules permit SR2008No27 for Mobile Plant

Soil stabilisation is an established earthworks process, pioneered by Powerbetter over many years, since 1980’s

—

The Powerbetter Mix-in-Place treatment processes are now widely recognised as an effective and efficient means of constructing pavements and foundations with significant savings in construction costs

—

Land Remediation -Immobilise and stabilise contaminants within either a loose or solid matrix

—

As a general rule of thumb, most soil conditions encountered can be modified or stabilised to achieve enhancement -typical soils treated include both cohesive and granular materials, chalks, glacial till, mudstones and silts.

DYNAMIC... RAPID IMPACT COMPACTION (RIC-9T), up to 5m deep

DYNAMIC... RAPID IMPACT COMPACTION (RIC-9T),

up to 5m deep

Impulse Compaction (IC)

Rapid Impulse Compaction (RIC)

Deep Impact Compaction (DIC)

“Impact compaction is the repeated dropping of a weight onto the ground surface and is one of the simplest and most basic methods of compacting loose, soils or fills”

(Building on fill: geotechnical aspects 3rd edition -Charles & Watts 2015)

All “impact compaction” processes; inclusive rapid impact compaction (RIC) are classified as “ground improvement without admixtures in non‐cohesive soils or fills”, under A5 classification set out by the International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE) technical committees on ground improvement (TC17 & TC211)

CLASSIFICATION OF GROUND IMPROVEMENT

METHODS ADOPTED BY ISSMGE-TC17

A5. Surface compaction (including rapid impact compaction)

Compaction of fill or ground at the surface (up to 5m deep)

The Rapid Impact Compaction (RIC-9T) ground improvement method is carried out by dropping a hydraulically lifted 9,000kg hammer, in free-fall from an average drop height nominally 0.9m (sensor controlled), onto a 1.5m diameter circular steel footplate in order to compact soils in-situ up to 5m deep

Powerbetter apply treatment across platform surface areas on a pre-defined drop design, utilising on-board GPS guidance to auto-locate every RIC-9Tdrop point accurately and ensure the entire site has been accurately treated in accordance with the predefined grid configuration.

The number of RIC-9T drops (nine tonne weight x 0.9m drop height) is defined by average induced settlement application design cut-off criterion measured, recorded and auto-stopped by the on-board RIC-9T telemetries

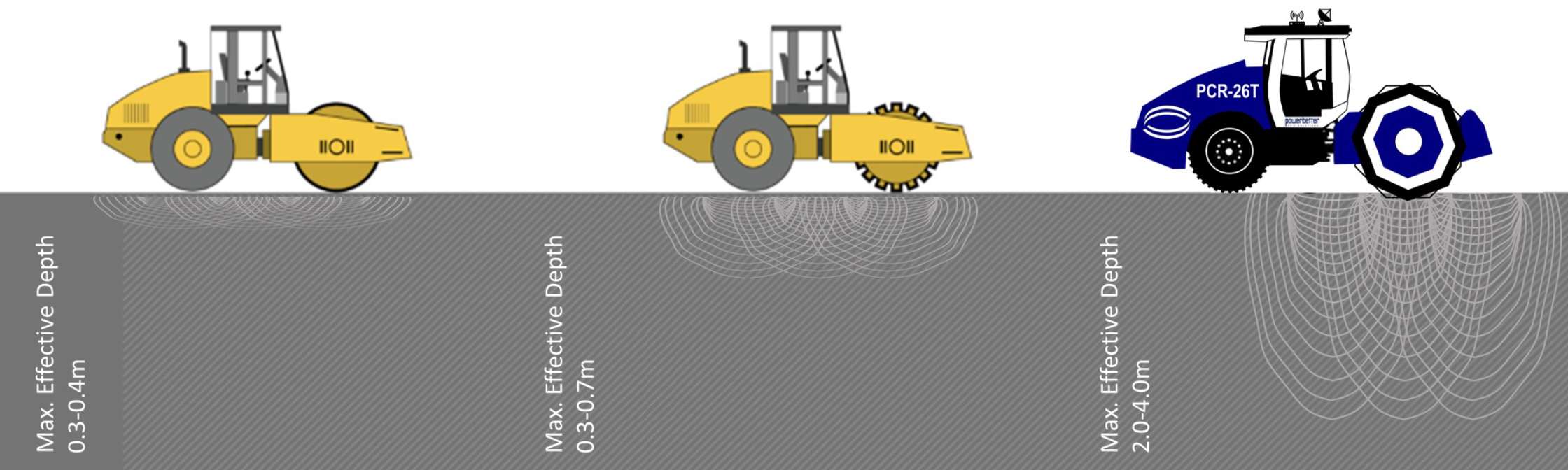

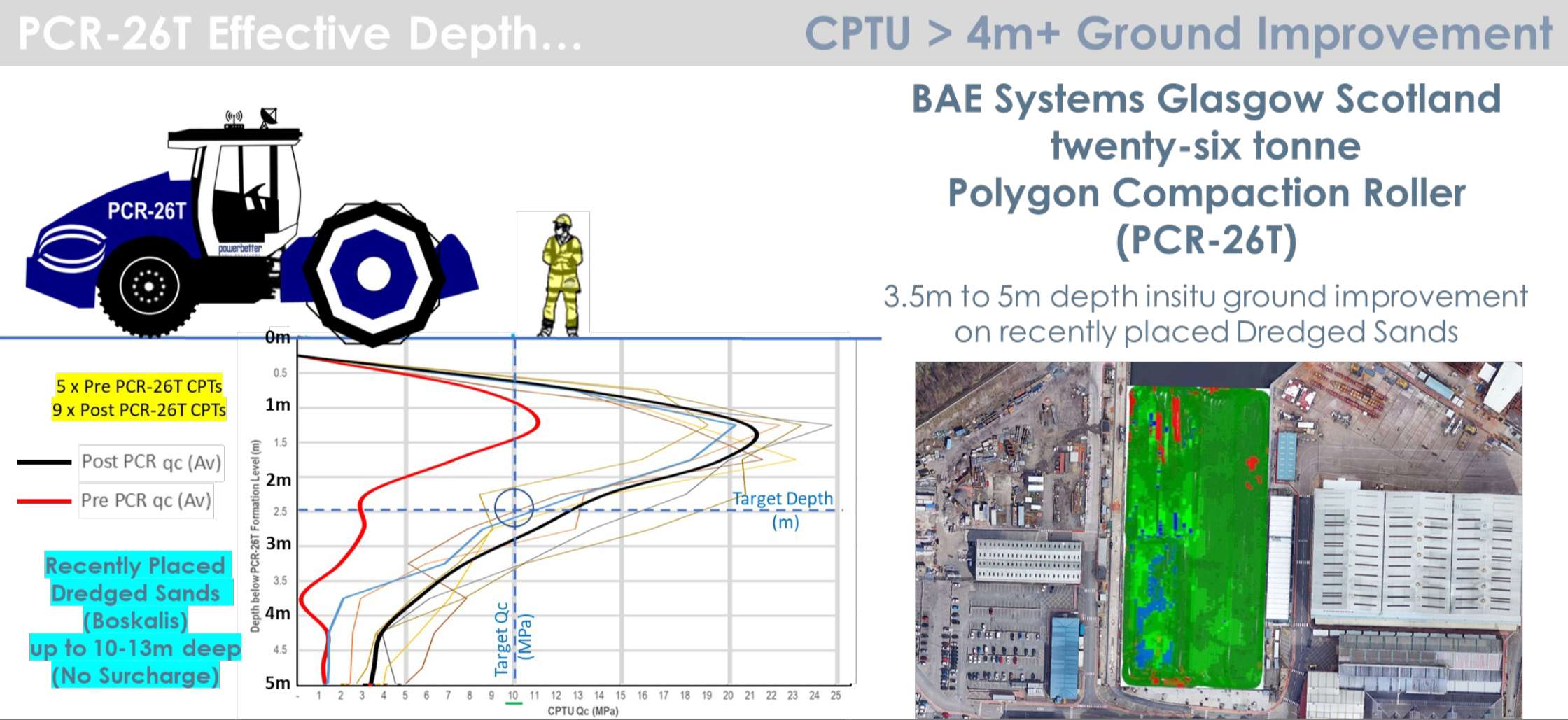

ROLLING… POLYGON COMPACTION ROLLER (PCR-26T), up to 3m deep

ROLLING… POLYGON COMPACTION ROLLER (PCR-26T),

up to 3m deep

Rolling Dynamic Compaction (RDC)

High Energy Impact Compaction (HEIC)

“Impact compaction” processes; inclusive rolling dynamic compaction (RDC) are classified as “ground improvement without admixtures in non‐cohesive soils or fills”, under A5 classification set out by the International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE) technical committees on ground improvement (TC17 & TC211).

The Polygon Compaction Roller (PCR-26T) method is the densification of soils at constant water content. Compaction (densification) is achieved through the application of mechanical energy to soil such that the air void volume is decreased, increasing soil density.

The PCR-26Tmechanical energy causes a rearrangement of the soil structure into a denser configuration.

CLASSIFICATION OF GROUND IMPROVEMENT METHODS ADOPTED BY ISSMGE-TC17

A5. Surface compaction

Compaction of fill or ground at the surface (up to 3m deep)

The Polygon Compaction Roller (PCR-26T) application system comprises a 26-tonne self-propelled roller, with the compaction drum split into three octagonal sections forming a polygonal drum.

Within the polygonal drum, a vibratory engine with specific oscillating counterweights is mounted, which can be rotated to change the direction of the compacting force in order to affect different depths of treatment.

Further to this, the dynamic energy from the vibrating engine can also be modified and matched to the ground response. PCR-26T is constantly applied with multiple vibratory impact passes until a set auto design cut-off criterion is met.

WARRANTY... VALIDATION - VERIFICATION

THE PERFORMANCE AND UNIFORMITY OF RIC-9T & PCR-26T

Continuous Compaction Control (CCC)

Ground Impact Response Dynamic Compaction Control (GIRDCC)

RIC-9Ts and PCR-26Ts are fitted with on-board Ground Impact Response Dynamic Compaction Control (GIRDCC) telemetry sensors which constantly measure various aspects of the response of the ground to the effects of the dynamic / impact / rolling compaction at each RIC-9T drop position and PCR-26T location.

The digital records taken of the ground using GIRDC Care then used to assess the performance and uniformity of the ground improvement progress during treatment and the identification of any areas where the requisite improvement is not been achieved (potential soft spots).

25,000m2 RIC-9T GIRDCC monitoring data for 18 No. container crane rail-lines (each 400m long)

Head Office for Powerbetter Developments

The Nookin, 48 Leeds Road, Oulton, Leeds, West Yorkshire, LS26 8JY

—

T: +44 (0) 1132 822 488

E: enquiries@powerbetter.biz

—

East Anglian Region

Contact Mike Burton

T: +44 (0) 1603 337532

mike.burton@powerbetter.biz

—